Imagine converting every analog gauge, mechanical switch, and visual indicator in your facility into a smart digital sensor using nothing more than an inexpensive camera and AI. This isn’t science fiction—it’s the industrial AI revolution happening now, and CameraVision is leading the charge.

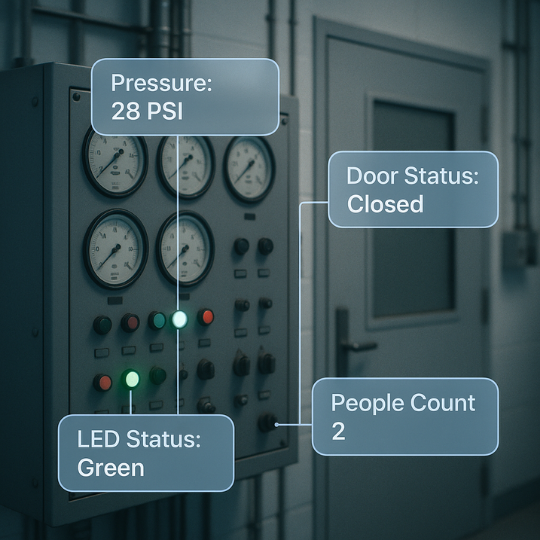

Most manufacturing facilities today have dozens of security cameras capturing everything, but their SCADA systems remain completely “blind” to critical visual conditions. Pressure gauges show readings that operators must manually check and record. Door positions go unmonitored until someone physically inspects them. Equipment status lights blink away, noticed only when problems have already escalated into costly downtime.

This visual intelligence gap represents one of the largest untapped opportunities in industrial automation. While your existing camera infrastructure captures a wealth of operational data, that information exists in isolation—disconnected from the control systems that could act on it immediately.

The economic impact is staggering. Manual monitoring processes consume countless labor hours while missing optimization opportunities that automated systems would catch instantly. Equipment failures go undetected longer than necessary. Safety violations occur without immediate alerts. Environmental conditions drift beyond optimal ranges before anyone notices.

CameraVision changes everything. Our AI-powered industrial automation platform transforms any existing camera into an intelligent sensor that seamlessly integrates with your industrial protocols. No expensive infrastructure overhauls. No complex retrofitting projects. Just plug-and-play AI intelligence that bridges the gap between your visual assets and operational systems.

With CameraVision, that analog pressure gauge becomes a precise digital sensor feeding real-time data to your SCADA system. Loading dock doors automatically report their status to your logistics management platform. Equipment indicators trigger immediate alerts when conditions change. All using the cameras you already have installed.

How It Works

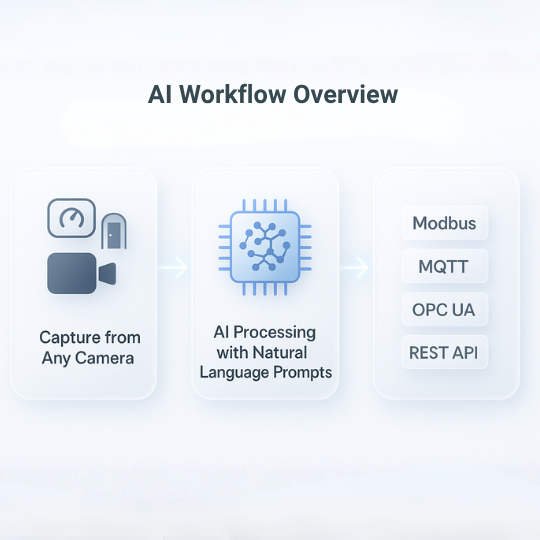

CameraVision transforms visual information into actionable industrial data through a simple three-step process that works with any camera and integrates with any industrial system.

Step 1: Capture Images from Any Camera

The system captures video and images from a wide range of cameras—from existing security cameras to industrial IP cameras to simple USB webcams. No special hardware required. If it can capture an image, CameraVision can use it.

Step 2: Process with Customizable AI Prompts

Instead of complex computer vision programming, you simply write natural language prompts describing what you want to measure or detect. CameraVision processes these images using your choice of LLM—cloud-based services like OpenAI, Azure, or Google, or open-source models running locally on your network.

Example Prompts:

- “Is the door open or closed? Return ‘Open’ if it’s open and ‘Closed’ if it’s closed”

- “What is the pressure reading on this gauge? Return the numeric value in PSI”

- “What temperature is shown on this display? Return the numeric value in Fahrenheit”

Step 3: Convert to Industrial Data Formats

Results are returned as clean digital data—Open/Closed, True/False, numeric values (28 PSI, 160°F), or text descriptions. CameraVision automatically converts this data into the protocols your systems need: Modbus TCP, MQTT, OPC UA, REST APIs, webhooks, or any other industrial communication standard.

Multi-Point Data Extraction: Prompts can return multiple data points from a single image:

- “Are there any people in this area? (true/false). How many people are present? Return numeric count.”

- “Is the pump running? (true/false). What is the pressure reading? Return PSI value. Any visible leaks? (true/false).”

This simple approach eliminates the need for specialized computer vision expertise while providing enterprise-grade reliability and security.

Why CameraVision is Different

CameraVision takes a fundamentally different approach to industrial vision. Instead of complex computer vision programming, we use simple natural language prompts that anyone can write and understand. Instead of expensive proprietary hardware, we work with any camera you already have installed.

Flexible Deployment Options

Edge Processing: Deploy on small, inexpensive devices like Raspberry Pi for local processing. Perfect for remote locations or air-gapped networks.

Cloud Processing: Use powerful cloud AI services for maximum accuracy and capability. Ideal for facilities with good internet connectivity.

Hybrid Approach: Combine local and cloud processing for the best of both worlds—immediate local responses with advanced cloud analytics.

Universal Protocol Support

CameraVision speaks the languages your industrial systems already understand:

-

Modbus TCP for PLCs and SCADA systems

-

MQTT for IoT platforms and cloud connectivity

-

OPC UA for modern manufacturing execution systems

-

REST APIs and Webhooks for custom applications

-

BACnet (coming soon) for building automation systems

Simple Architecture, Powerful Results

Camera Interface: Works with most ip cameras, no driver installation or special configuration required.

AI Processing: Your natural language prompts are processed by leading AI models to extract exactly the data you need from images.

Protocol Output: Converts AI results into the industrial data formats your systems expect—Modbus registers, MQTT messages, OPC UA variables, or custom APIs.

Web Management: Configure everything through a simple web browser. No specialized software to install or maintain.

Enterprise Security: All connections are encrypted and outbound-only, so no firewall changes are needed. Your network security stays intact.

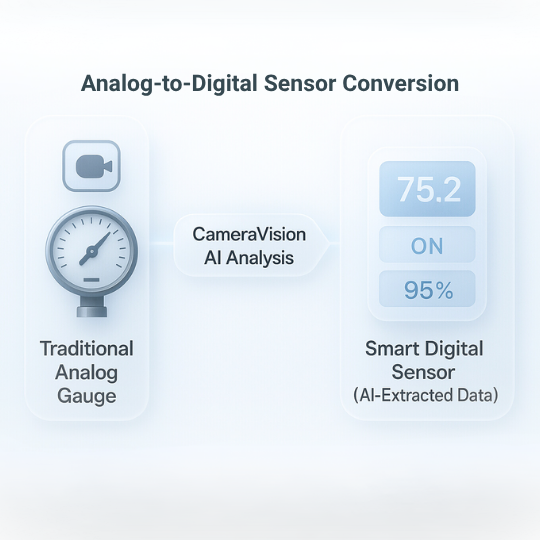

Analog-to-Digital Sensor Conversion

The most transformative CameraVision application replaces expensive analog sensor upgrades with intelligent camera analysis. Instead of installing $5,000 digital pressure transmitters, a low-cost camera connected to CameraVision can read mulitple analog gauges and indicators with equivalent accuracy and far superior cost-effectiveness.

ROI calculations become compelling when $300 camera installations replace $5,000 transmitter upgrades while providing equivalent functionality.

Consider a chemical processing facility with hundreds of mechanical pressure gauges installed throughout the plant. Traditional digitization would require replacing each gauge with a digital transmitter, running new cables, and updating control system I/O configurations. Total project costs easily reach six figures while requiring extensive downtime for installation.

CameraVision enables gauge reading automation without touching existing instrumentation. Cameras positioned to view analog displays use AI prompts like “Read the pressure value from this gauge” to extract numeric readings that feed directly into SCADA systems. Existing mechanical indicators provide visual confirmation while digital integration enables automated trending, alarming, and process optimization.

Implementation requires only camera positioning and prompt configuration. No electrical work, no process interruptions, no expensive transmitter purchases. ROI calculations become compelling when $300 camera installations replace $5,000 transmitter upgrades while providing equivalent functionality.

Real-world deployments demonstrate remarkable accuracy. Properly configured camera systems achieve ±1% reading precision on quality analog gauges, matching or exceeding many digital sensors. Environmental compensation algorithms account for lighting variations and viewing angle changes that could affect accuracy.

Operational Status Detection

Door and gate monitoring represents the most immediately valuable CameraVision application for many facilities. Loading dock doors, security gates, and equipment access panels provide critical operational information that’s traditionally monitored manually or not at all.

Loading dock management exemplifies the operational value. Warehouse management systems need real-time door status to optimize truck scheduling and inventory movement. Traditional solutions require expensive door position sensors and complex wiring installations. CameraVision cameras positioned to view dock areas use prompts like “Is loading dock door 3 fully open?” to provide binary status outputs through standard Modbus connections.

Equipment state recognition extends beyond simple open/closed detection to complex operational status assessment. Pump running indicators, valve position displays, and LED status lights become intelligent sensors feeding operational data to control systems. Multi-state detection handles complex scenarios like “pump running normally,” “pump running but low flow,” and “pump stopped” based on visual indicators operators already monitor.

Configuration examples demonstrate practical implementation:

{

"camera_id": "dock_door_1",

"prompt": "Is the loading dock door completely open?",

"output_type": "binary",

"modbus_mapping": {

"register_type": "coil",

"address": 1001

}

}This simple configuration maps door status to Modbus coil 1001, enabling immediate integration with existing control systems without programming changes or additional I/O hardware.

Infinite Automation’s AI Vision

CameraVision represents the first step in Infinite Automation’s comprehensive vision for AI-native industrial operations. While visual intelligence provides immediate value, our roadmap extends AI capabilities across every aspect of industrial automation and control.

Our commitment to accessible AI solutions drives technology choices that prioritize ease of deployment over complexity for its own sake. Edge-deployable architectures, natural language configuration interfaces, and standard protocol integration ensure AI benefits reach organizations regardless of their technical sophistication or IT resource levels.

CameraVision establishes the foundation for more advanced AI capabilities by creating reliable data pipelines and operational integration patterns. Success with visual intelligence applications builds organizational confidence and technical infrastructure for expanding AI adoption across broader operational scenarios.

The convergence of AI, edge computing, and industrial automation creates unprecedented opportunities for intelligent manufacturing systems that adapt and optimize autonomously.

Ready to Close Your Visual Intelligence Gap?

📊 Free Visual Intelligence Assessment: We’ll help you identify and quantify your highest-value opportunities. Most facilities uncover significant ROI potential within the first consultation.

Want to learn more about our AI automation approach? Explore our AI automation services or discover how we help businesses think AI-first.

Schedule a Call to discuss how CameraVision can transform your operations.